SEARCH

Automobile Products

Automobile Products

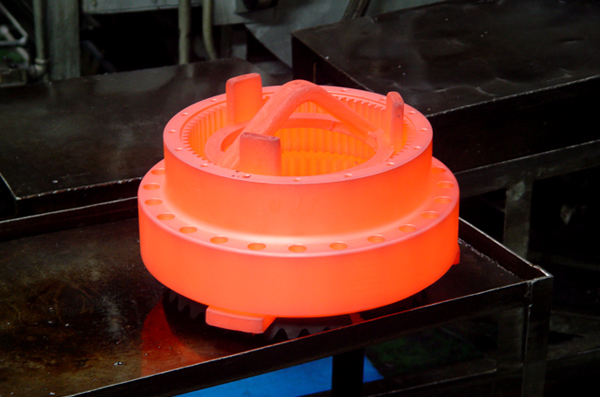

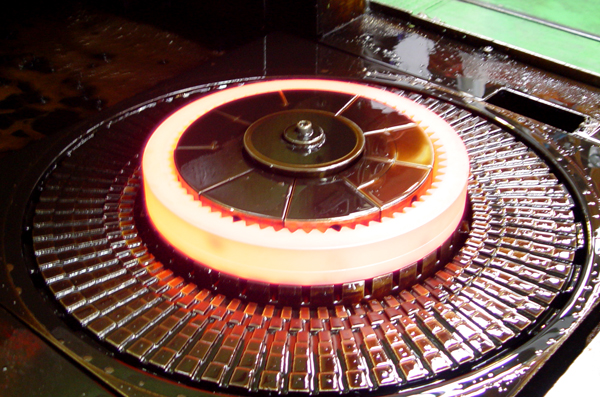

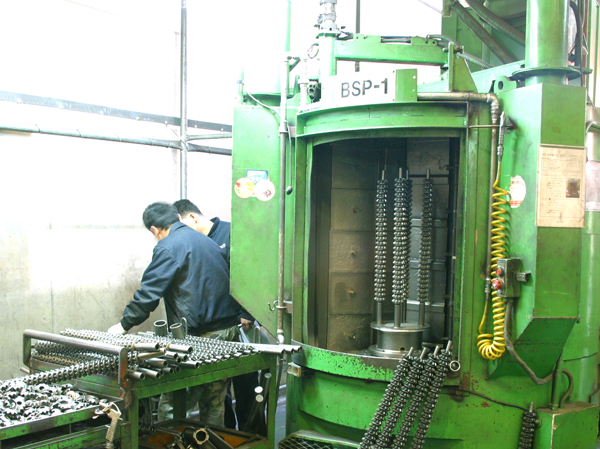

Direct quenching of transmission parts for automobile, press quenching processing of large bevel pinion / ring gear for axle, processing volume of 5,000 ton/year.

Cementation equipment specialized in bevel gear for small axle, processing volume of 700 ton/year, capability to produce 300,000 ring gears per year.

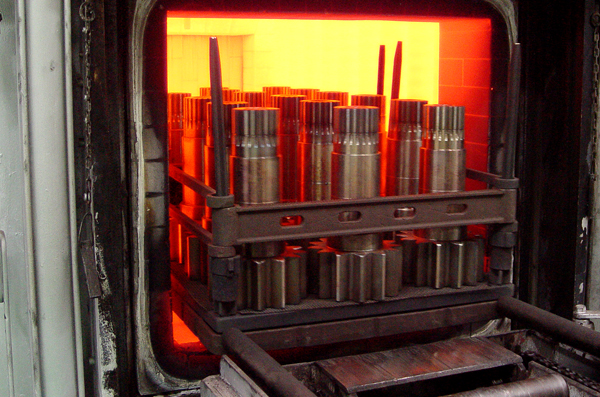

Facilities for the direct quenching of automobile and other device parts, processing volume of 500 ton/year.

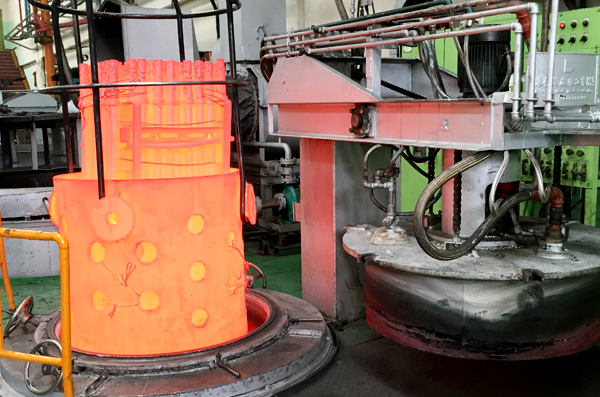

Heat treatment of large gear for ships, processing volume of 400 ton/year, has pit-type cleanser and tempering.

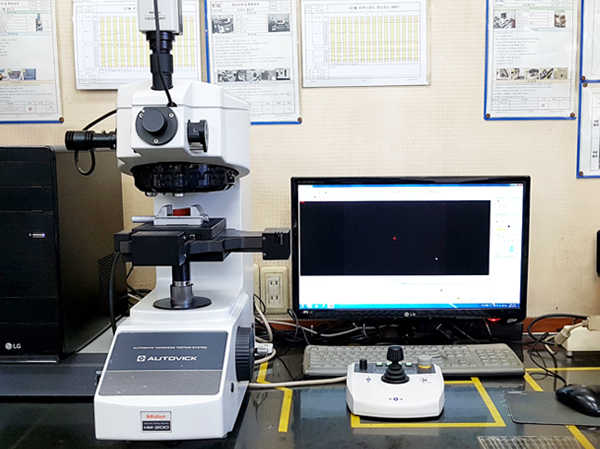

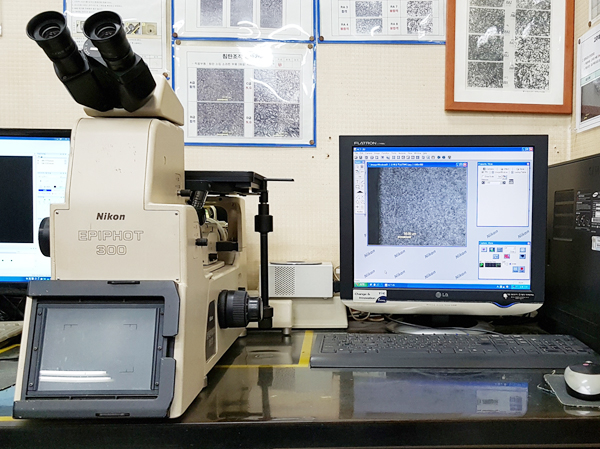

Has heating efficiency, saves energy, and enables the heating of private parts. Enhances resistance against abrasion and fatigue occurring on the surface since it enables quick heating and cooling. Has little oxidation, decarbonization, and, degeneration, good work environment, and little air pollution.

If you inquire online, we will respond as soon as possible.

Online Inquiry