TONGIL INDUSTRIES CO.,LTD.

- Company

- General info.

- CEO Greeting

- History

- Organization

- CI

- Location

- HR & Recruitment

- Ideal Candidates

- HR System

- Welfare and Benefits

- Recruitment

- Recruitment Inquiries

- Business

- R&D

- R&D introduction

- Organization

- Research Areas

- Automobile Division

- Grinder Division

- Ball Screw Division

- Software Inventory

- Certification

- Automobile Division

- Grinder Division

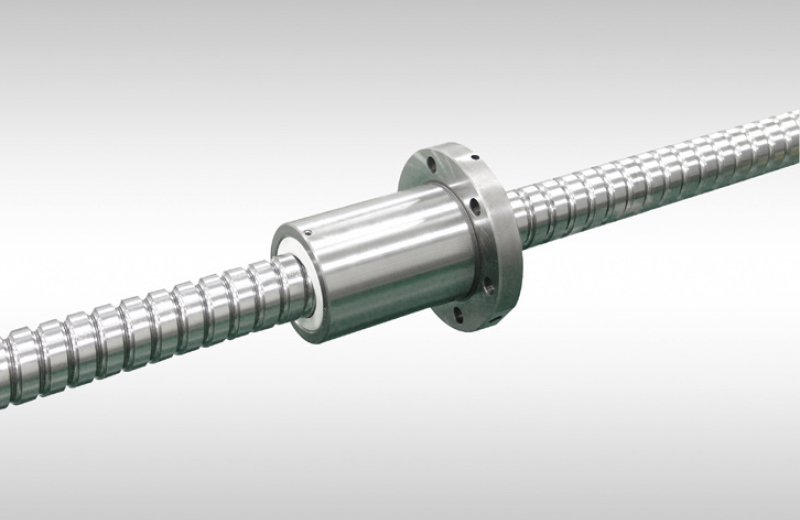

- Ball Screw Division

- Sustainable Mgmt.

- CS Center

- CS Center

- Notice

- Online Inquiry

- Catalog

- PR Center

Any specific products of interest?

Quicklinks

R&D Research Areas

The Best Partner for Your Needs

Continuous focus on new product development and research

As a specialized manufacturer of ball screws used in various types of machine tools and industrial machinery, we are committed to meeting the diverse needs of our customers. We continuously invest in research and development for new product innovations, ensuring high load-bearing capacity, low noise, and the timely release of advanced products.

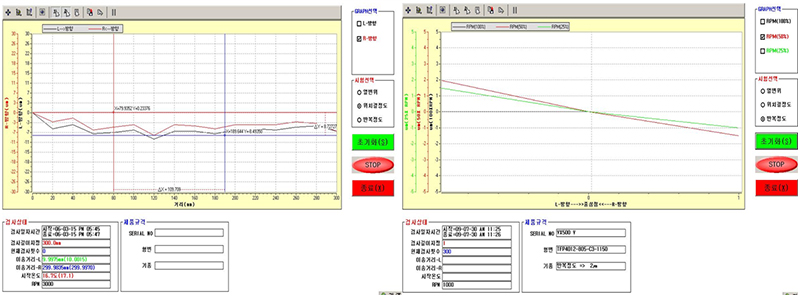

R&D activities

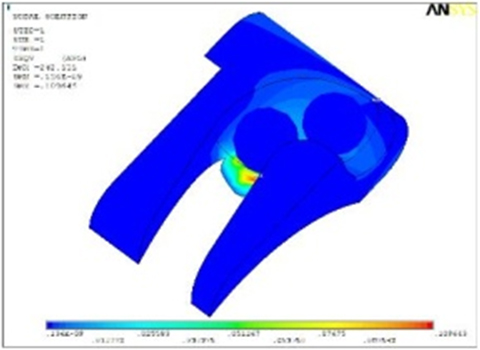

- 01 Modeling

- 02 Analysis

- Positioning Accuracy Test / Noise Test / Thermal Deflection Test / Repetition Test

- 03 Test Evaluation

- Comprehensive Testing Equipment

New Product Development

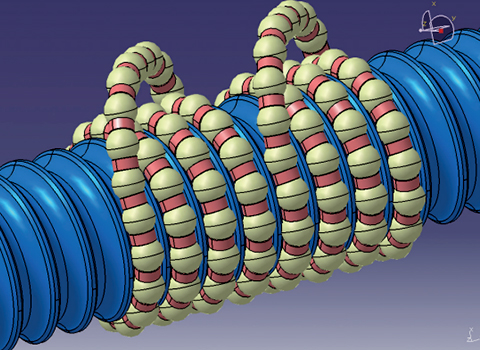

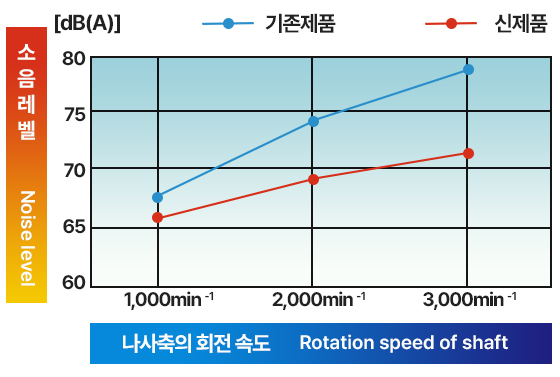

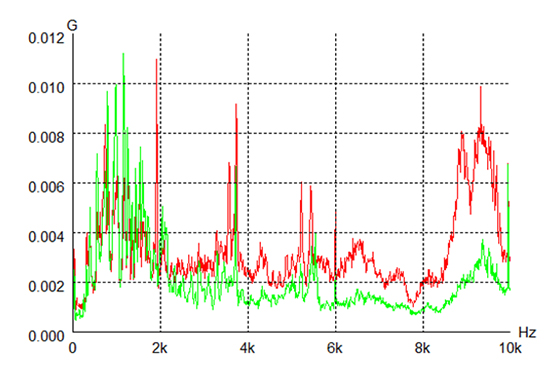

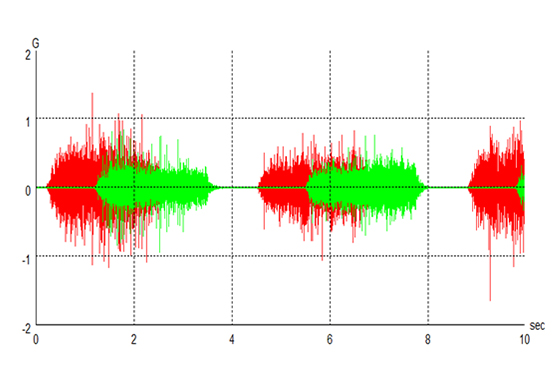

Low Noise High-Speed Ball Screw

- Features

- Improved ball circulation structure for low noise and excellent sound quality (structural measures for shock absorption)

- Noise reduction through changes in component materials (low impact noise specifications)

- Improved accuracy of thread trajectory shape (enhanced trajectory shape and surface roughness)

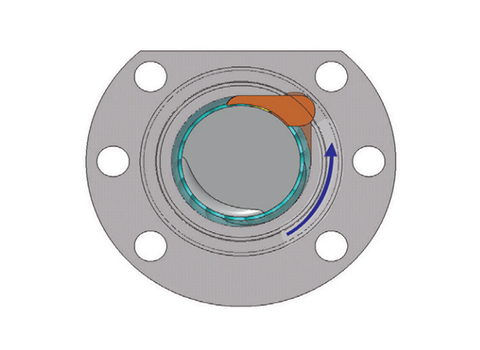

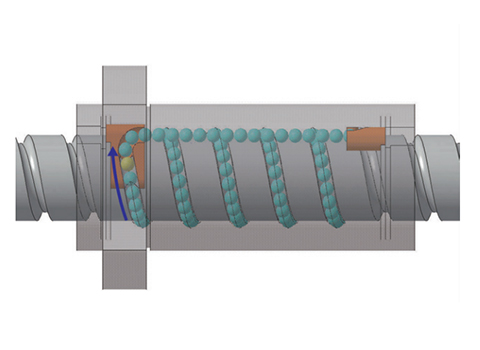

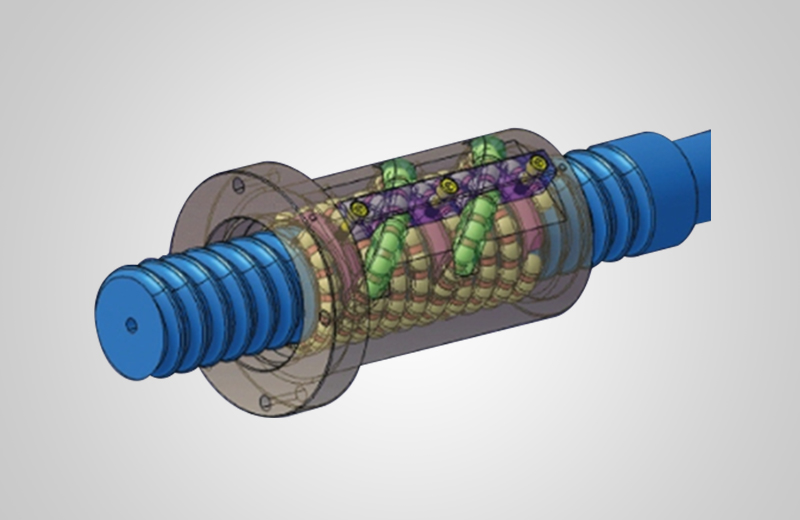

Structure

Circulation in the tangential direction

Circulation in the tangential direction Circulation in the lead angle direction

Circulation in the lead angle direction

Performance

Comparison of noise levels between the existing product and the new product

Comparison of noise levels between the existing product and the new product FFT frequency analysis (vibration)

FFT frequency analysis (vibration) FFT frequency analysis (amplitude of sound intensity)

FFT frequency analysis (amplitude of sound intensity)

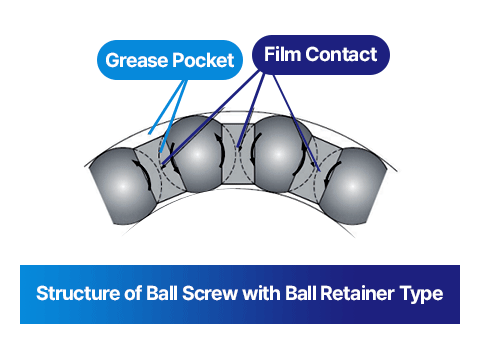

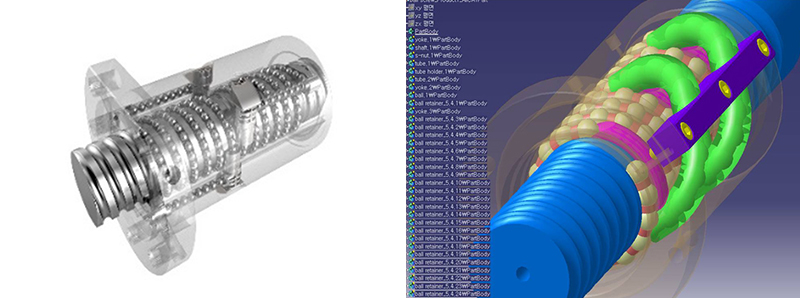

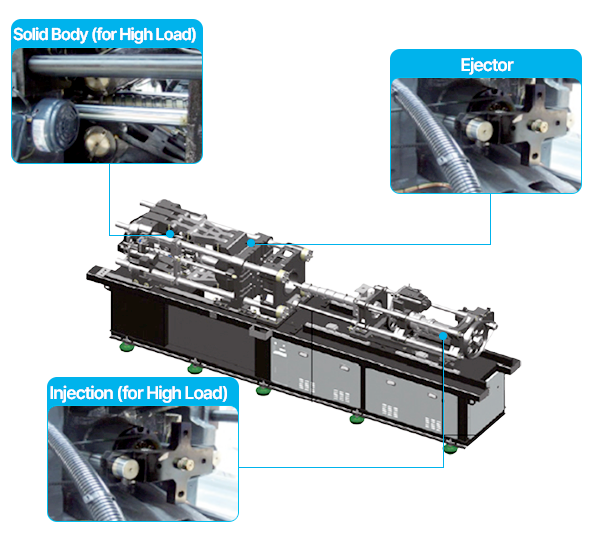

Development of High Load BallScrew for Injection Molding Machines

- Features

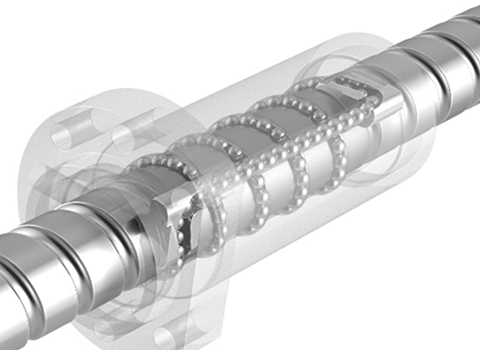

- Optimal design for high load and long service life, achieving 2-3 times the rated lifespan compared to conventional designs (considering ball retainer, ball contact angle, curvature radius, and number of windings)

- Design of the ball circulation components for high-speed operation and high load capacity

- Application of a lubricative retainer to eliminate ball-to-ball contact, resulting in low friction and low torque (eliminating the need for long-term lubrication)

Structure

Recommended Installation

Performance

| Item | General | High Load | |

|---|---|---|---|

| Material | SHAFT | SCM445H (High-Frequency Heat Treatment) | SCM440H (High-Frequency Heat Treatment) |

| NUT | SCM420H | SCM420H | |

| Contact Angle | 45 ˚ | 50 ˚ | |

| BALL SIZE | 3.175 ~ 9.525 | 12.7 / 15.875 / 19.05 | |

| Curvature Ratio | 55% | 52% | |

| TUBE(Circulation Components) | TUBE | YOKE&TUBE , Injection Tube | |

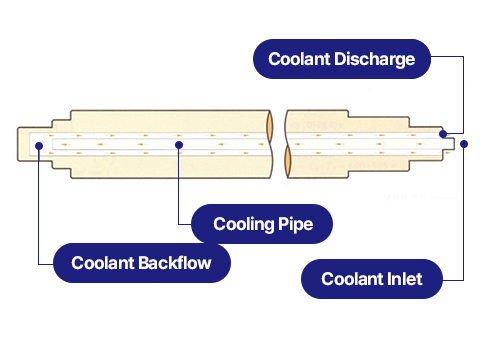

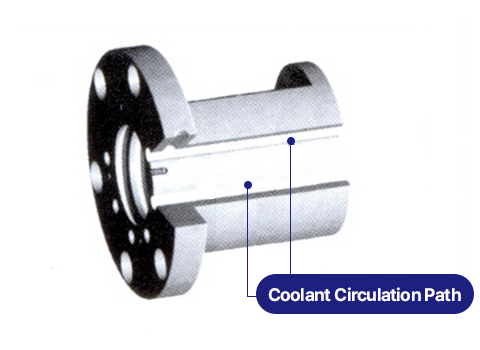

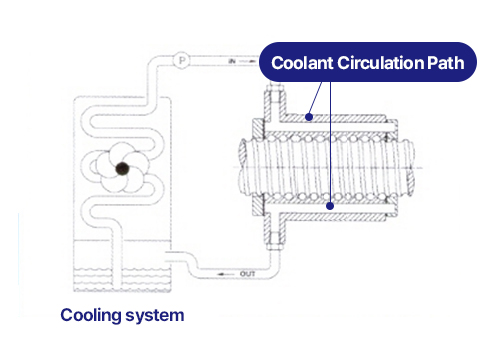

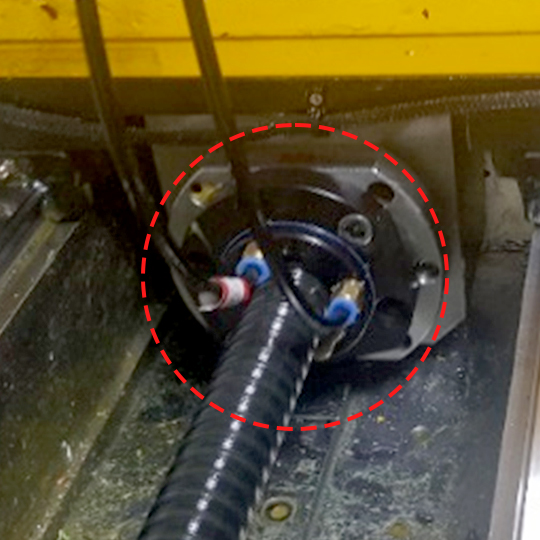

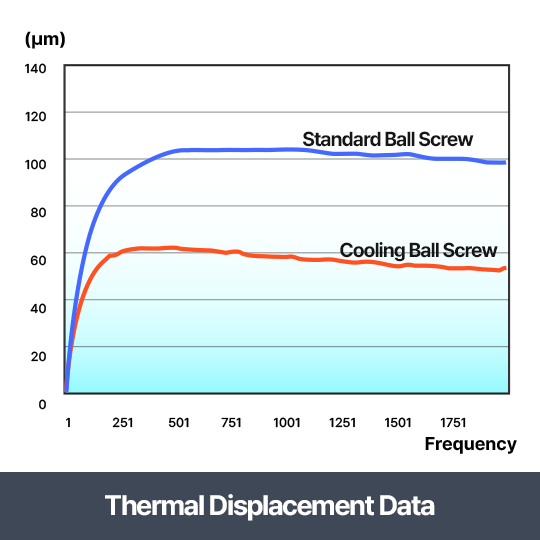

Development of Cooling Ball Screw

- Features

- Incorporation of a cooling circulation channel in the shaft and nut to introduce a coolant and manage temperature

- Suppression of temperature rise for improved performance during high-speed rotation

- Minimization of thermal displacement in the Ball Screw to increase durability and lifespan

Structure

Cooling Test for the Ball Screw

-

Test Conditions Spec YEF4010-R670-C3-1091 Shaft Diameter ø 40 Lead 10 Torque 3.5~4 kgf·cm Effective Number of Turns 5 Maximum Speed 30m/min Weight 150kg

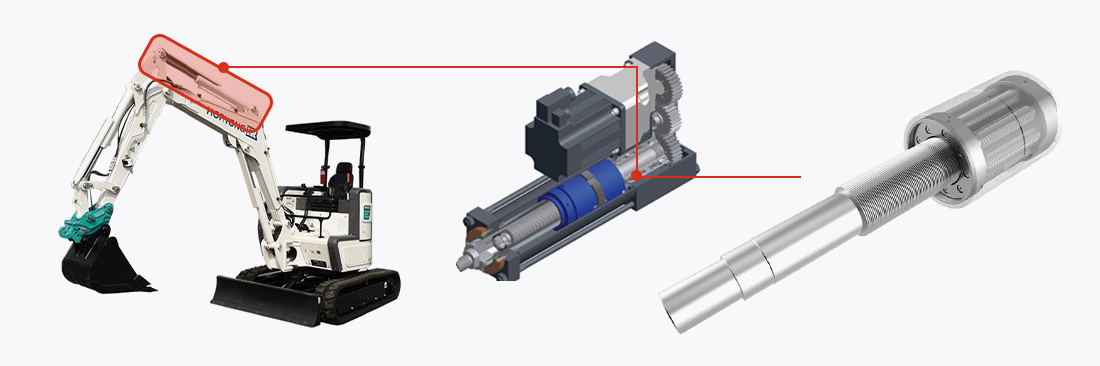

Development of Roller Screw for Construction Machinery

R&D activities and achievements

| Year | Research activities and development achievements |

|---|---|

2022 |

Development of Roller Screw for Construction Machinery |

2021 |

Development of Ball Screw for Small Modular Reactors (SMR) and Thermal Power Plants |

2020 |

Development of 120mm Artillery Ball Screw |

2019 |

Development of Measurement Equipment for Noise and Vibration in Machine Tools with Ball Screws |

2018 |

Development of Hollow Type Cooling Ball Screw for Shaft and Nut |

| Development of High Load Ball Screw for Injection Tube Parts | |

2017 |

Development of High-End Ball Screw for Machine Tools |

2016 |

Development of Compact Ball Screw for Semiconductor/Robot Applications |

2015 |

Development of High Load Durability Testing Machine |

| Development of High Vibration Seal | |

2014 |

Introduction of Shaft Wrapping Device |

2012 |

Development of Ball Screw for Cheonmu Ammunition Loading and Transfer |

2011 |

Development of High Load Ball Screw for Injection Molding Machines |

2010 |

Development of Ball Screw for Electric Vehicle Steering and Braking Systems |

| Development of Ball Screw for Directional Adjustment of Grenades | |

2008 |

Development of High Load Retainer Type Ball Screw |

2006 |

Development of EndCap Internal Circulation Ball Screw |

2005 |

Development of Ball Screw for K10 Ammunition Loading |