SEARCH

Automobile Products

Automobile Products

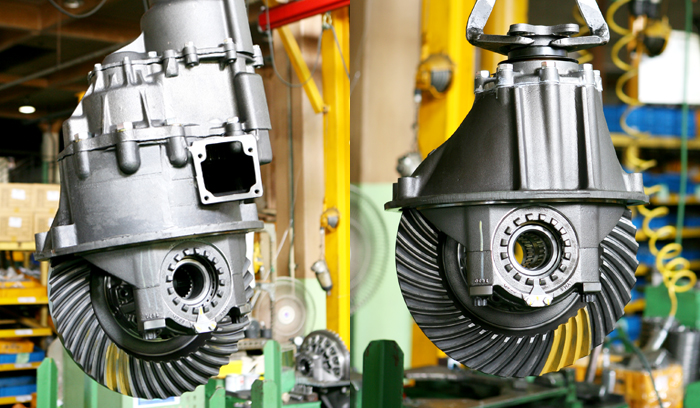

We utilize the DRY CUTTING method to manufacture GEAR SETs for RV, SUV, and small trucks. This gear cutting process involves precise machining techniques, which not only enhance the quality of the products but also allow for a 1.8 times increase in production compared to conventional methods. Additionally, this machining line incorporates advanced technology and automation, addressing noise-related issues effectively.

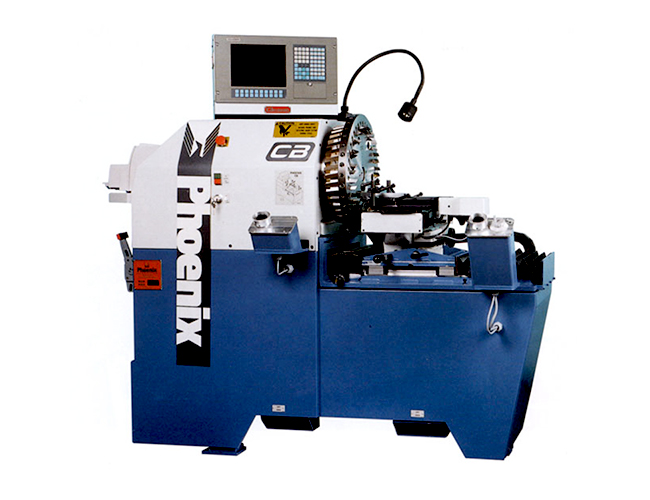

Using lapping oil and compound, it uses the cutting edge facility imported from Gleason, the world best company, for final lapping of geat set.

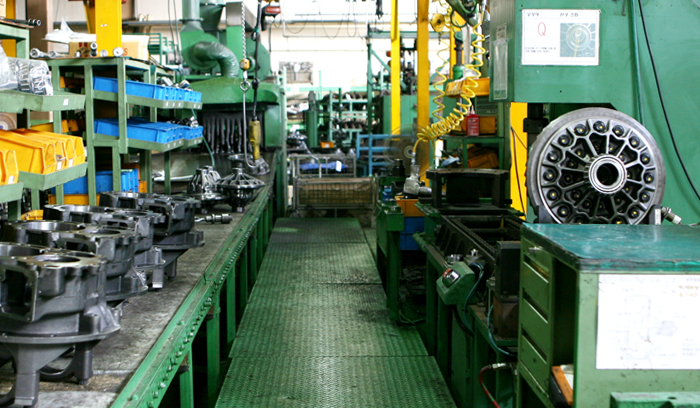

It is an assembly line that produces products mounted on automobile that requires high power and high intensity. Continuous research and invest has been being made for big and small Carrier Ass'y, and Axle Ass'y development.

| Category | Facility status | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Factory 1 | Cutting | Lapping | Cleaning | ||||||

| Cutting M/C | Cutter Grinding | Cutter Assembly | Cutter Inspection | Lapping | Test | Deburring cleaning | Laser marking machine | Cleaning machine | |

| 17 | 3 | 2 | 3 | 15 | 19 | 15 | 4 | 1 | |

| Total | 79 | ||||||||

If you inquire online, we will respond as soon as possible.

Online Inquiry