SEARCH

Automobile Products

Automobile Products

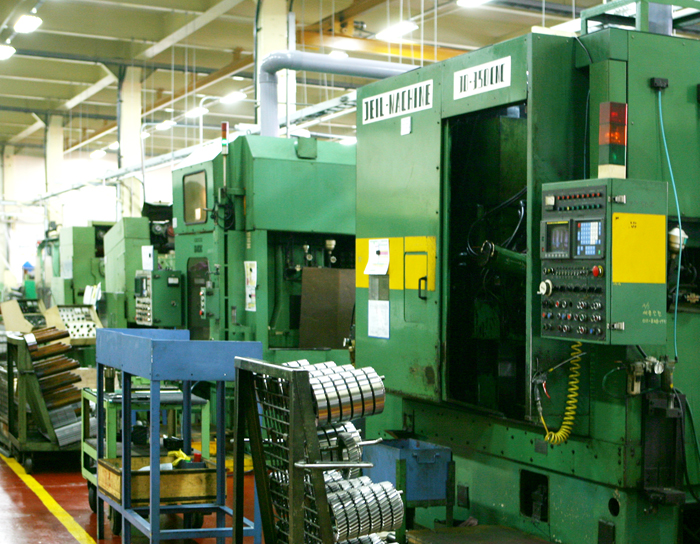

We have optimized our production line by incorporating HOBBING M/C, SHAPING M/C, and SHAVING M/C as the core equipment. In addition, we have installed a broaching line and a beam welding machine line to maximize operational efficiency. Our equipment enables us to achieve external machining up to a maximum diameter of Φ360 × ℓ700 and internal machining up to Φ400 × ℓ120.

COUNT SHAFT AUTOMATION LINE is the latest line facility that can automate and manufactures the products of multi-phase GEAR (6 gear processes) of COUNTER SHAFTS for small and medium-sized trucks. / Equipment composition / Main production items

| Category | Facility status | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Factory 1 | Hobbing | Shaper | Broach | Drill | Chamfering | Rounding machine | Milling | Shaving | Grinding | Tooth Grind | Universal lathe | Stabbing Sorter | ||

| 20 | 12 | 2 | 2 | 6 | 1 | 2 | 10 | 8 | 2 | 3 | 1 | |||

| Total | 69 | |||||||||||||

If you inquire online, we will respond as soon as possible.

Online Inquiry